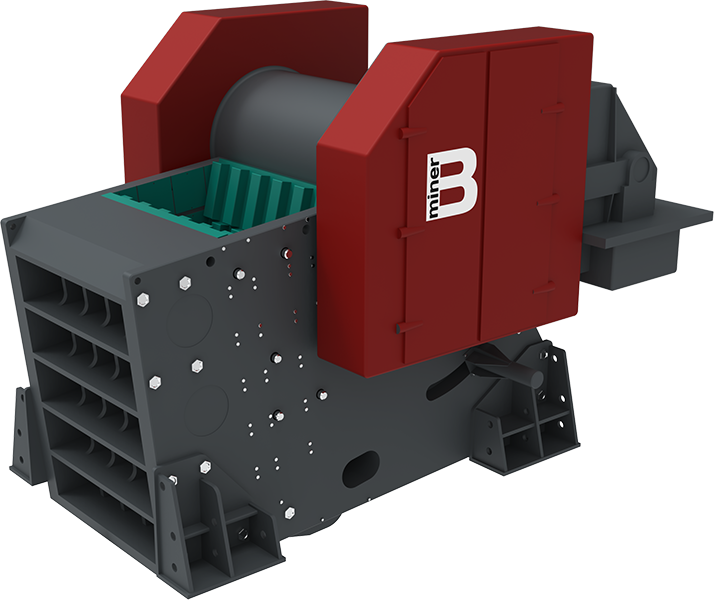

Jaw crushers B-miner BM-JC series

B-miner JC Jaw crushers are used in mining industry for primary crushing. They reduce material size for following stages of crushing and can be used in non-metallic minerals production as well. This type of crushers can provides larger volumes of material; therefore it makes them accepted alternative to gyratory crushers.

Frame without weld seams at bolt and finger joints is the basis of jaw crusher. This design provides excellent fatigue strength and crushing efficiency rate.

Frame of B-Miner BM-JC jaw crusher is made of molded pieces and has a honeycomb structure, which make it robust and heavy-duty.

Excellent capacity and crushing efficiency rates

Easy process of installation and maintenance

Great opportunities due to wide range of options

B-miner BM-JC jaw crushers may be equipped with optional devices to solve any technical task.

Flywheel and gear safeguards can be installed for personnel protection from spinning parts of the crusher.

Optional engine mount allows to set up driving engine directly at the backside of crusher to decrease installation dimensions.

Loading hopper provides continuous feeding of material from the feeder to the crusher. Lifting devices for crushing plates, jaws and toggle plates are included in basic configuration.

Technical features jaw crushers B-miner BM-JC

| Power, kW | Speed, rpm |

Feed opening size, mm |

Capacity range, t/h |

Basic weight, kg | |

| B-miner JC80 |

75 (100 h.p) |

350 | 800х510 | 335-515 | 7670 |

| B-miner JC96 |

90 (125 h.p) |

330 | 930х580 | 390-592 | 10150 |

| B-miner JC106 |

110 (150 h.p) |

280 | 1060х700 | 500-760 | 15650 |

| B-miner JC116 |

132 (175 h.p) |

260 | 1150х760 | 520-800 | 19240 |

| B-miner JC120 |

160 (200 h.p) |

230 | 1200х870 | 540-800 | 27990 |

| B-miner JC130 |

185 (250 h.p) |

220 | 1300х1000 | 831-1267 | 40150 |

| B-miner JC150 |

200 (300 h.p) |

220 | 1400х1200 | 880-1319 | 50950 |

| B-miner JC160 |

250 (350 h.p) |

220 | 1600х1200 | 1145-1909 | 71330 |

| B-miner JC200 |

400 (500 h.p) |

200 | 2000х1500 | 1435-2462 | 12510 |

Jaw crushers can be supplied both as stationary equipment with supporting steel frames and as semi-trailer on wheels, which provide its mobility and optimizes costs of service.