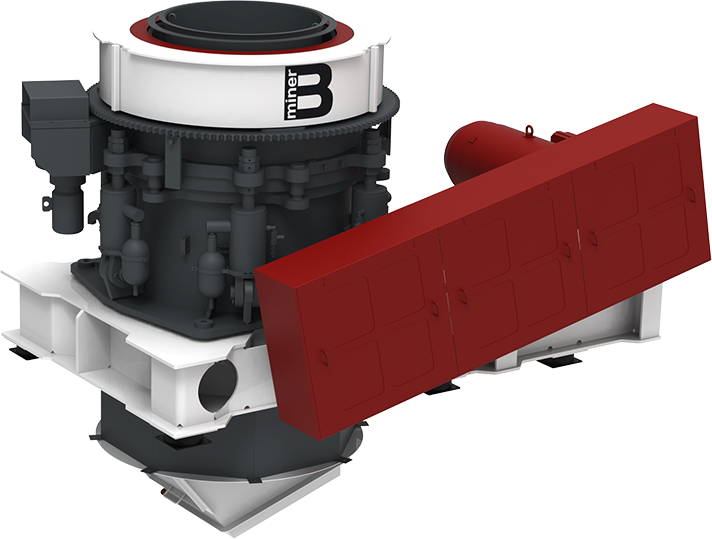

Cone crushers BM-MHP series

B-Miner cone crushers are characterized by an optimal combination of capacity, eccentricity and crushing chamber design.

These crushers are the optimal solution for the secondary, tertiary and quaternary crushing, and suitable for materials with any characteristics.

The design solution of B-miner MHP cone crushers provides increased throughput and produce the end product with required granulometric composition.

In comparison to other equipment in the class, these crushers are more productive and have a higher reduction ratio at the same level of power usage.

Cone crushers are capable to produce fine end products, reducing the number of required crushing stages and therefore increase economic efficiency. One of the design features of cone crushers is convenient access to all the main elements from the top side of the crusher, the possibility of remote mechanical rotation of the bowl during dismantling and no need to use a compound. Double-acting hydraulic cylinders for discharging metallic inclusions ensure non-stop operation and reduce downtime.

Cone crushers B-miner BM-MHP technical features

| Max. feed size, mm | Max. engine power, kW |

Capacity range, t/h |

CSS size range, mm |

Amount of crushing chambers | Weight, kg | |

| BM-MHP200 | 185 | 132 | 90-250 | 10-38 | 4 | 12160 |

| BM-MHP300 | 241 | 220 | 115-440 | 10-45 | 5 | 18100 |

| BM-MHP3 | 220 | 250 | 100-390 | 8-45 | 5 | 16100 |

| BM-MHP400 | 304 | 315 | 140-630 | 10-51 | 5 | 25600 |

| BM-MHP4 | 252 | 315 | 135-555 | 8-45 | 5 | 25800 |

| BM-HP500 | 351 | 355 | 175-1200 | 10-51 | 5 | 37000 |